浙江省杭州市蕭山區(qū)瓜瀝鎮(zhèn)工農(nóng)村(杭甬高速公路瓜瀝出口往南500米右拐)

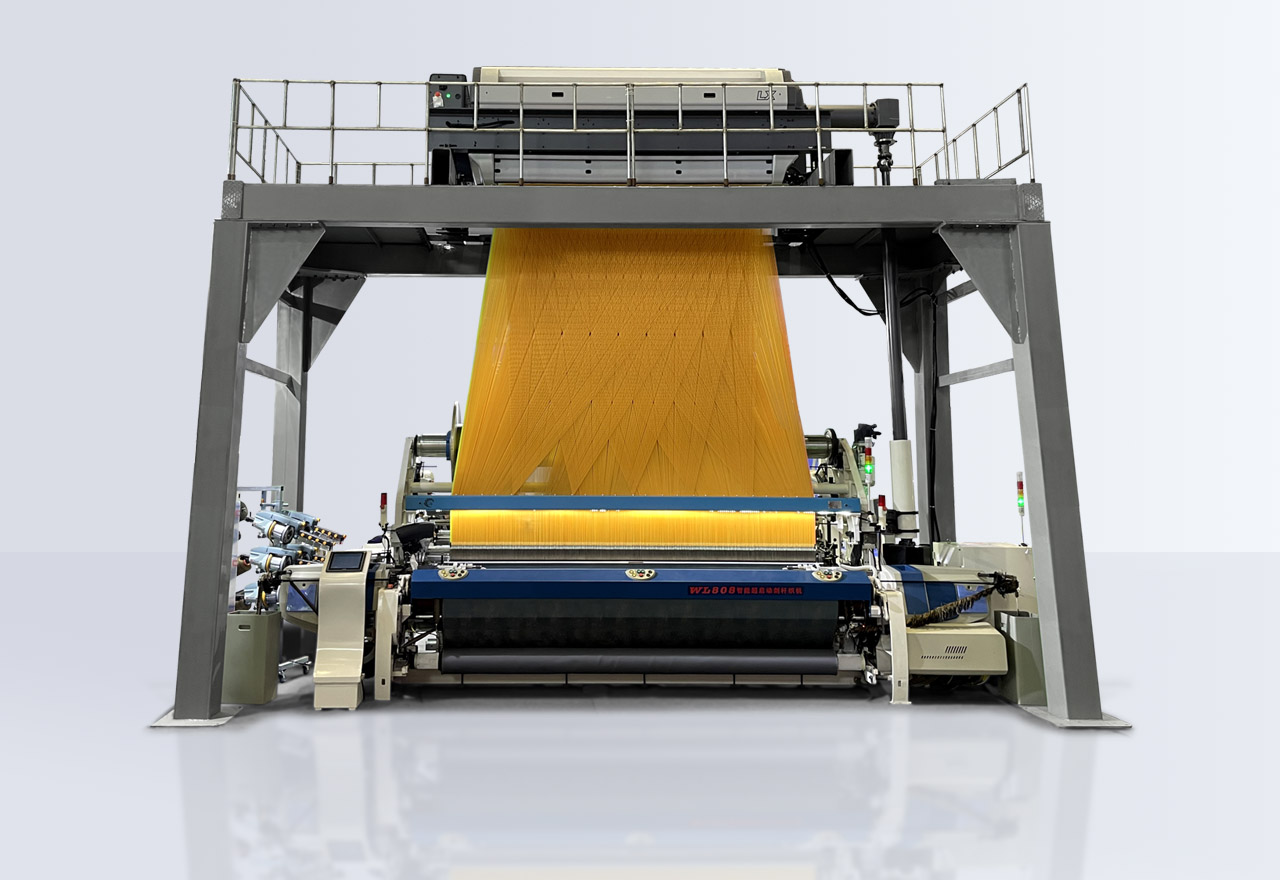

碳纖維織機(jī)

-

碳纖維織機(jī)

-

瀏覽人數(shù)

次

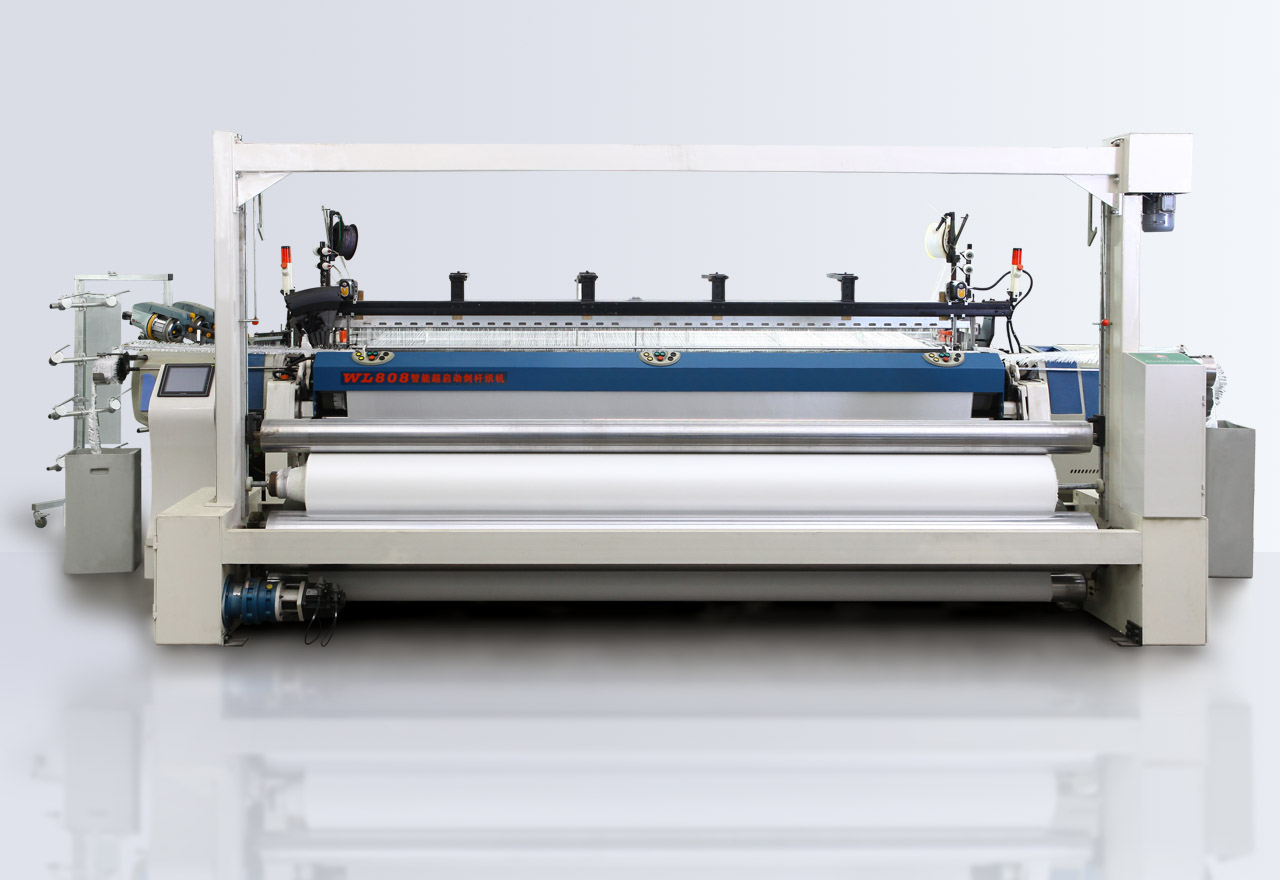

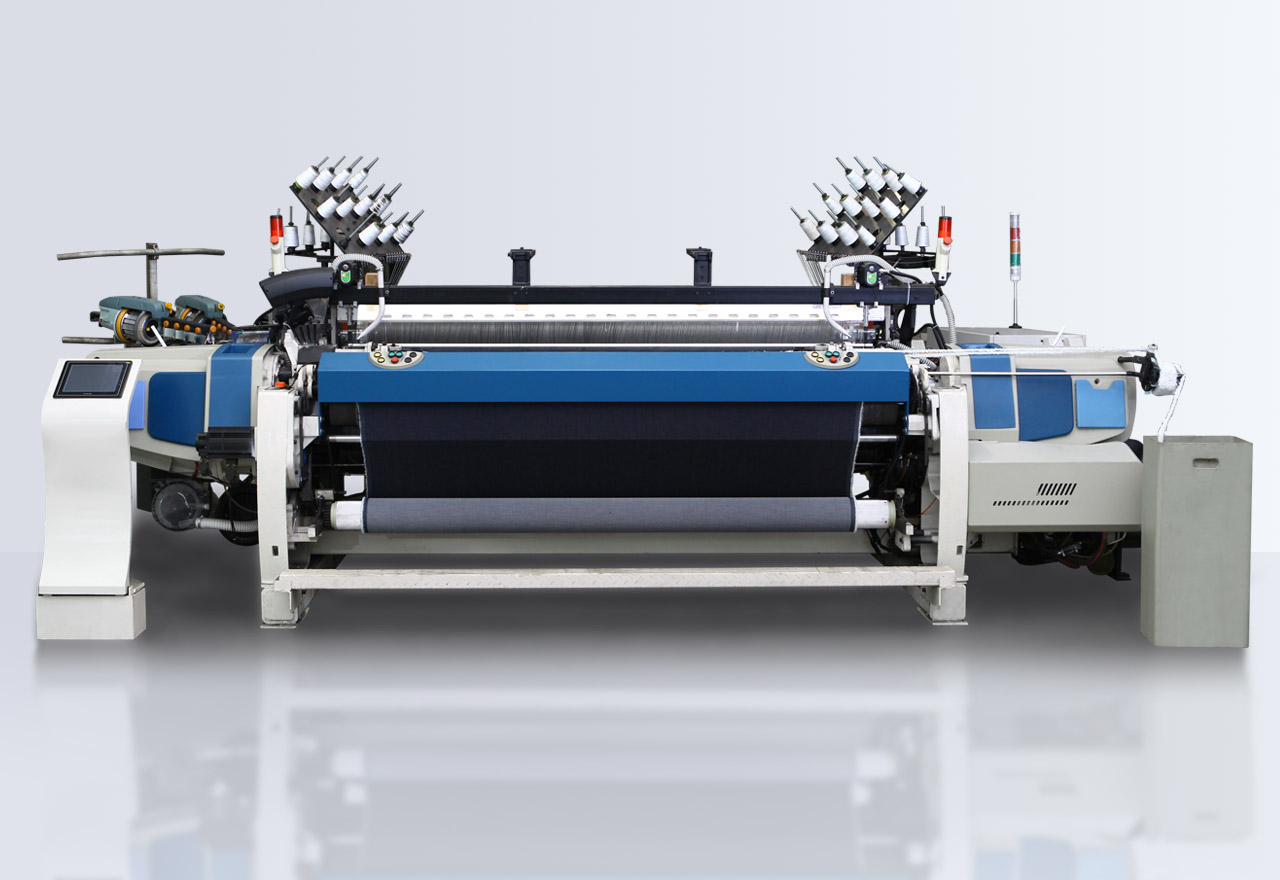

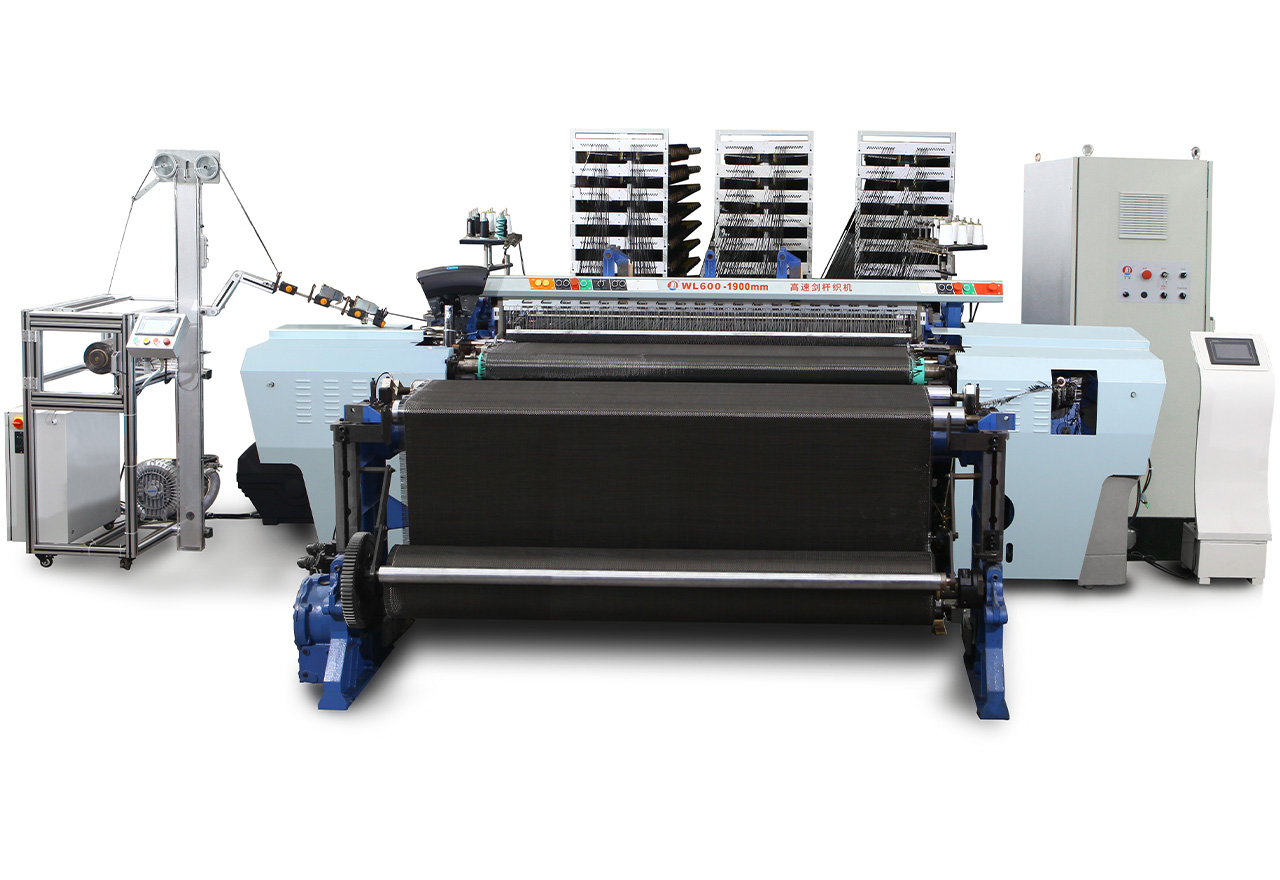

WL600 碳纖維劍桿織機(jī)技術(shù)指標(biāo):

WL600是一款專業(yè)織造碳纖維布的織機(jī),可以織造經(jīng)緯向均為纖維的方格布、箱包布等,也可以織造徑向?yàn)樘祭w維、緯向?yàn)闊崛劢z的碳纖維單向布,集碳纖維放絲、織造、熱定型、布卷成型于一體。主要技術(shù)要求:

1、纖維紗線適用范圍:1K、3k、6k、12K、24K、25K.

2、門幅規(guī)格:150CM、190CM、230CM.

3、選色:單色或2色及以上,

4、開(kāi)口機(jī)構(gòu):電子多臂,適用于復(fù)雜組織結(jié)構(gòu),也可配踏盤,適用于簡(jiǎn)單組織結(jié)構(gòu)。

5、送經(jīng):電子送經(jīng),送經(jīng)均勻,張力穩(wěn)定。

6、卷取:電子卷取,緯密精確到0.1緯/厘米,范圍:0.8-20緯/厘米。

7、卷繞成型:成品端面整齊,卷裝直徑最大800mm。

8、自動(dòng)尋緯:斷緯紗后可以實(shí)現(xiàn)一鍵自動(dòng)尋緯倒綜,確保緯密均勻,避免停車檔產(chǎn)生,

9、設(shè)備潤(rùn)滑:噴淋潤(rùn)滑、油浴潤(rùn)滑、油嘴加油潤(rùn)滑,

10、自動(dòng)控制:織機(jī)速度變頻調(diào)節(jié)、具有定位停車、定位開(kāi)車、斷經(jīng)自停、斷緯自停等功能.

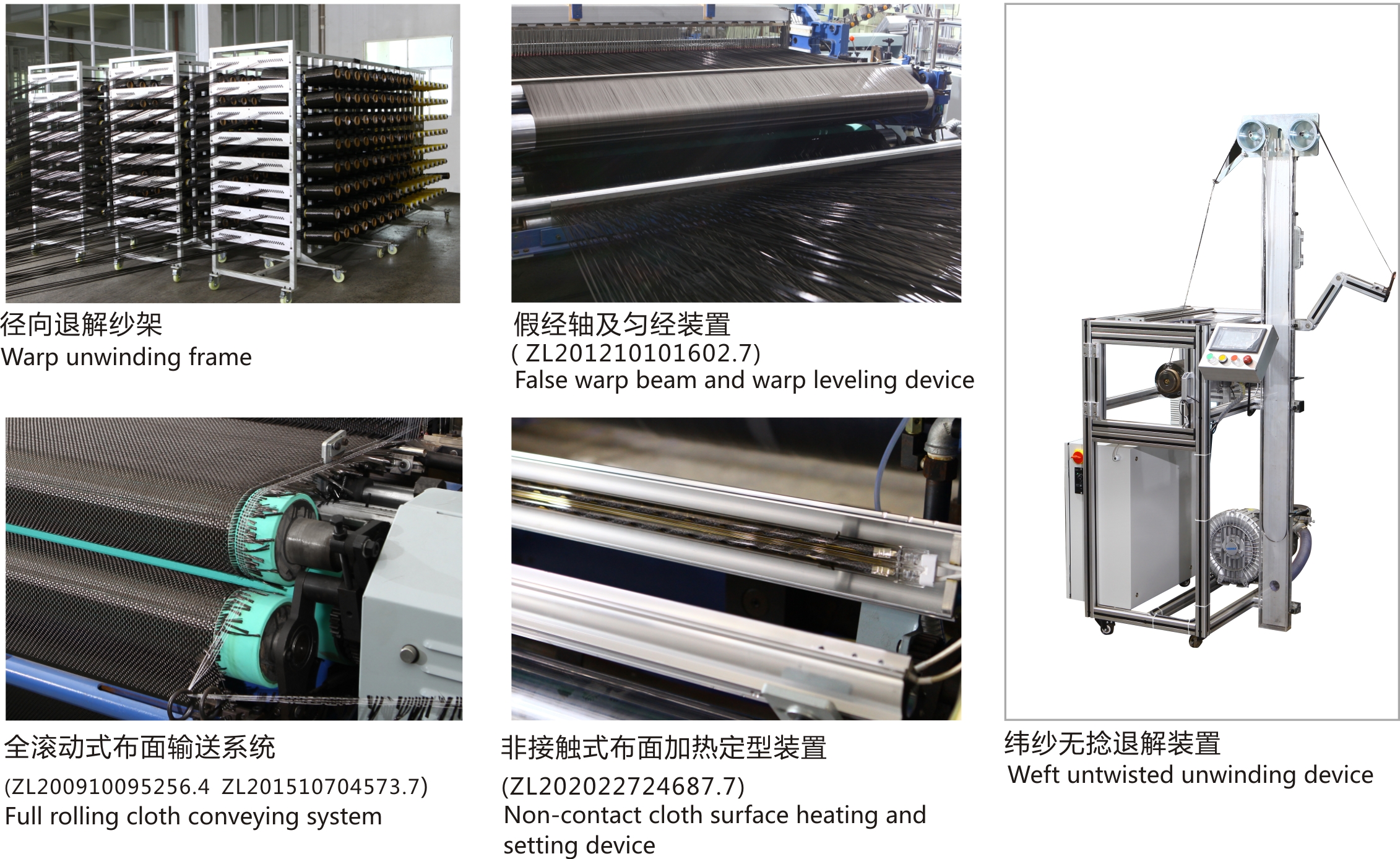

11、紗架:徑向退解,退解張力由彈簧調(diào)節(jié),

12、緯紗:徑向退解、同服電機(jī)驅(qū)動(dòng)緯紗退解、采用空氣負(fù)壓均衡緯紗張力。

13、主電機(jī)功率:5.5KW或4.0KW

WL600 CARBON FIBRE RAPIER LOOM TECHNICAL DATA:

WL600 carbon fiber rapier loom is a professional weaving machine for carbon fibercloth. lt can weave square cloth, luggage cloth, etc. with carbon fiber in the warp and weftdirections, and can also weave carbon fiber sheets with carbon fiber in the radial directionand thermal use in the weft direction. Directional fabric, which integrates carbon fiber weftand weaving, weaving, heat setting, and roll forming.Main technical requirements:

1.Scope ofapplication of fiber yarn: 1K,3k, 6k,12K,24K,25K.

2.Width specification: 150CM, 190CM, 230CM.

3.Color selection: single color or 2 colors and above.

4.Opening mechanism: Electronic dobby, suitable for complex organizational structures.

5.Let-off: Electronic let-off, uniform tension and stable let-off.

6.Take-up: Electronic take-up, the weft density is accurate to 0.1 wefucm. Windingforming: the end face of the finished product is neat, and the maximum diameter of thepackage is 800mm.

7. Automatic weft-seeking: After the weft yarn is broken, one-key automatic weft-seekingand rewinding function can be realized to ensure uniform weft density.

8. Equipment lubrication: spray lubrication, oil bath lubrication, oil nozzle lubrication.

9. Automatic control: the loom speed is adjusted by frequency conversion, with functionssuch as positioning stop, positioning start, warp breaking automatic stop, and weft breakingautomatic stop.

10. Creel: radial unwinding, the unwinding tension is adjusted by spring.

11. Weft yarn: radial unwinding, servo motor driven weft yam unwinding, and air negativepressure to balance weft yarn tension.

12.Main motor power: 5.5Kyy or 4.0KW.